Pallet racking

Variable, like your requirements

You want to store different types of goods on pallets in your warehouse? In that case you should make sure to look at the STILL pallet racks. With direct access to each individual pallet and the high safety standards, STILL pallet racks are the best possible solution for variably warehouse requirements. Thanks to its high flexibility this rack type can be configured very individually.

Benefits – overview:

- Comfortable access to all articles

- Easy stock level monitoring

- Optimum adaptability to the warehouse space as well as to weight and dimensions of the goods

- Flexible and cost-efficient storage: Possibility to store different load carriers in a single type of rack (euro pallets, industrial pallets, cage pallets, boxes, etc.)

- Allows to pick orders directly

Would you like additional information?

Our customer service team is available to happily answer any questions you have regarding pallet racks.

Download Technical Data (PDF)

Typical applications of the pallet rack

The STILL pallet racks meet a broad range of different warehouse requirements, for example, Wide aisle racking or Narrow aisle racking / high bay warehouse.

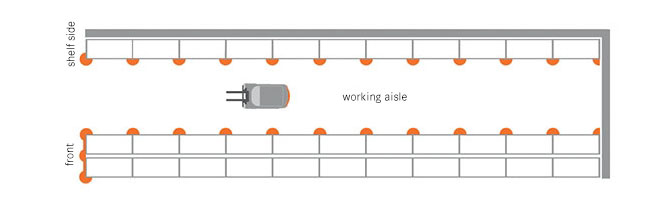

Wide aisle warehouse

The standard solution for pallet storage in the warehouse is a warehouse with wide aisles. The operation of the racks is usually carried out by counter balanced trucks, reach trucks or order pickers. The lower levels can be easily operated by hand pallet trucks or electric high lift trucks.

- Cost-efficient storage

- Easy operation of the racks with conventional industrial trucks

- Manual order picking on floor level

Narrow aisle warehouse/high bay warehouse

Racks with narrow aisles allow a high utilisation of warehouse space. The operation of the racks is usually carried out by manually operated VNA trucks/order pickers that can be deployed for order picking as well as to store and retrieve complete load carriers. Due to the large lift heights, the high bay warehouses can be operated by industrial trucks.

- Good usage of the available floor space and warehouse height

- Ideal for large numbers of articles and medium to high turnover

- No relocation of goods for order picking

Pallet racks – design

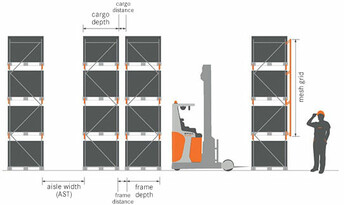

A pallet rack consists of a rack frame and cross beam. The rack frame is securely fixed to the floor with floor anchors. The cross beams are hooked into the rack frame. Depending on the load weight, different profiles and material thicknesses are deployed.

Of course, the design of the STILL pallet rack meets the requirements of regionally applicable standards and safety regulations.

A range of optional accessories guarantees individual safety and optimum flexibility. Buffer and push-through protection guarantee high safety in everyday use. Different shelving options allow a more flexible use of the STILL pallet rack.

Pallet racks – components

Support frame

The support frame consists of two supports that are connected with horizontal and diagonal beams. The frames are bolted. To optimise transport costs, the frames are assembled on-site.

Cross beams

Cross beams are usually box-type profiles with a hook welded to each end. The hook is used to attach the girder to the frame. Two cross beams (pair) connect two frames making up a shelf in the rack. On the cross beams pairs the pallets are stored. These can be hooked individually at the desired height in the support frame.

Distance pieces

Distance pieces connect two racks at a given distance. If the racks are fitted with a sprinkler system, the distance pieces are also used to mount the sprinkler pipes.

The distance between racks is specified by regional standards and regulations, for example, by the industrial safety authority in Germany. For euro pallets without load overhang, the default distance is 200 mm. If sprinkler pipes are installed or in case of load overhangs, the distance can be adjusted.

Pallet racks – main accessories

Rack protection

A number of different solutions is available to protect the rack against possible damages. One type of solution is used inside the aisles, the other type is used to protect the end face of the rack.

Protecting the supports at the end face

A corner guard guarantees the minimum required protection of the supports. In accordance with the German regulation BGR 234, the corner guard must be at least 300 mm high and must be fixed to the floor independently from the rack.

The collision guard, which protects the complete rack stand, is an alternative to the corner guard. It is mounted across the whole face end. Various versions are available – the central part can be made of wood or steel. STILL generally deploys steel, because this material is more resilient. The advantage of wood is that it is easy to replace in case of damage.

Protecting the supports in the aisle

This safety equipment protects the frame inside the aisle and is either mounted on the support or on the floor in front of it. The guards make much sense in narrow aisles and in warehouses with high turnover frequencies. If the truck lightly collides with the rack during storage or retrieval, it does not damage the support. The guards are available for different heights.

Push-through protection

The push-through protection is a safety component that stops the pallet from falling off the back of the rack. The protection is not intended as a stop.

Placement frame

Placement frames are ideal to safely store and retrieve low quality pallets in the rack, because they hold the pallet securely. They also allow storing pallets with the 1200 mm side facing the aisle (crosswise storage). A galvanised, cold-rolled placement frame can hold the enormous load of up to 1200 kg. Placement frames for containers are additionally fitted with guide rails at the sides and can optionally be equipped with a load stop. This helps to precisely store cage pallets.

Shelf floor

To make more flexible use of the rack, we offer a number of different shelf floors. All versions are available as place-on or fit-in solutions. Chip boards, for example, are available in thicknesses of up to 38 mm. Depending on the load situation, mesh grid shelves can be deployed in the same way as grid floors. We are happy to assist you in choosing the ideal option for your application.

Warehouse markings

Our solutions for warehouse markings give you the perfect overview. Consistent and comprehensive marking of all aisles and bays are the basis for efficient warehouse management. The signs for the aisles illustrate the principal layout of the warehouse. Mounted well visibly they provide clear orientation, also in large warehouses. The bay labels uniquely mark each storage place. We design the format of the labels and the printed information according to your individual requirements.

Important planning parameters

Load carrier

The load carrier is a single unit stored in a storage area (for example, a pallet with a load weighing 1000 kg). The weight of the pallet determines the required shelf and bay load.

Shelf load

The shelf load is the maximum load capacity of a shelf consisting of a pair of cross beams that holds several loading units.

Bay load

The bay load is the maximum load capacity of a racking bay in which several loading units are stored on top of each other (without loads that are stored on the floor).

Frame load

The frame load is the maximum load capacity of a rack frame. The value is determined by summarising all loads of the surrounding racking bays and dividing the sum by two.

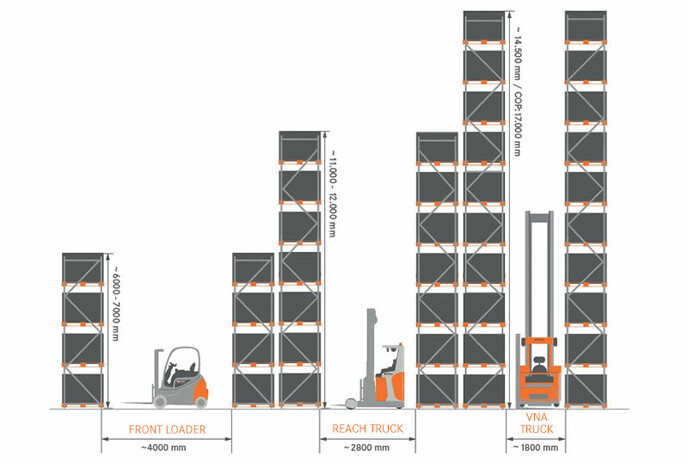

The drawing shows the relationship between rack levels, lift heights, the required trucks and working aisle widths. The warehouse truck and the rack must be matched and are planned in accordance with your requirements.

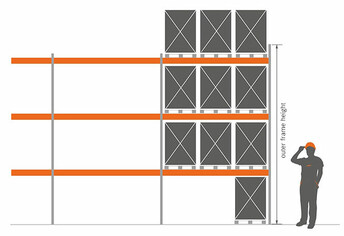

Important safety instructions

In order to ensure high levels of security in the warehouse, there are different regional security requirements.

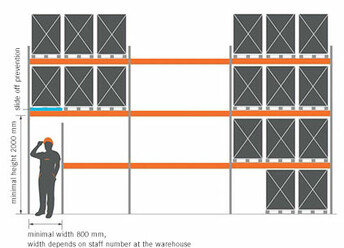

To secure load from falling over the side of the rack, the end faces of the rack must be at least 500 mm higher, measured from the top pair of cross beams or the top level (in accordance with BGR 234, Germany).

Faces not designed for storage or retrieval must prevent loads to drop from the rack. This can be achieved with a mesh grid at the back (in accordance with BGR 234, Germany)

Passageways for pedestrians inside the racks must have a minimum height of 2 metres. The height of passageways for trucks depends on the height of the vehicle: it must be at least 200 mm higher than the truck itself (in accordance with BGR 234, Germany).

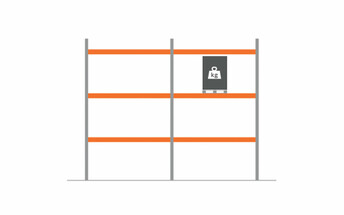

Rack label

The rack label is a mandatory item, because it shows important safety instructions as well as technical data, information on allowed load weights (bay load and field load) and information about the supplier. It must be attached to the end face of the rack.

Load capacity label

The load capacity label informs you about the order, rack type, technical information on load weights and safety instructions.

Buying pallet racks

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a pallet rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your pallet racks.

You would like to learn more about pallet racks before making a buying decision?

You can download technical specs. as a pdf using the link below:

Download Technical Data (PDF)

They are your racking experts for pallet racks:

| Maximum capacity (kg)Maximum lift height (mm) | |||

| up to 6066 mmup to 2000 kg | up to 7930 mmup to 2000 kg | up to 13000 mmup to 2500 kg | up to 14895 mmup to 1500 kg |