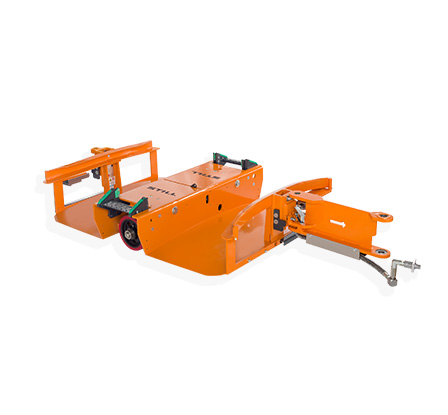

LiftRunner B-Frame

Efficient production supply with tugger trains

Highlights

- Loading and unloading from both sides for maximum flexibility

- Quiet operation and low wear-and-tear, as trolleys are raised up during the journey

- Excellent driveability and directional stability guarantees a high level of safety

- A straightforward easy-to-use trolley de-coupling system Safe handling with an automatic safety back-up when pushing trolleys

LiftRunner B-Frames are designed for different types and dimensions of trolleys up to a load capacity of 1000 kg. It offers maximum flexibility by means of the possibility of loading and unloading from both sides without de-coupling the frames. The LiftRunner tugger train system can therefore be used on alternative routes with little effort, or can deliver two different kinds of production line within one journey. The manoeuvrable two-wheeled frames are steered through a mid axle. This ensures excellent directional stability, even at high speeds and in braking manoeuvres. The combination of rigid and flexible links minimises jolting movements when starting off or braking and ensures a safe passage on ramps.

Trolleys slotted into the B-Frames are automatically secured by a mechanism and are lifted up when the driver enters the towing truck (standing truck) or activates a switch (seated truck). The lifting energy is provided by either pneumatics, hydraulics or electricity above the towing truck or autonomously above the frame. When the driver leaves the towing truck, the frames are lowered automatically and the trolleys can be removed. The trolley becomes disengaged via the foot pedal and can be removed effortlessly in a way that presents no strain to the back. B-Frames can be combined with C- or E-Frames within one train.

Power

- High load capacity and low deadweight: The load capacity of B-Frame is up to 1000 kg

- Efficient material transport: High handling capacity using bundled transports

- Individual deployment: With B-Frames transporting load carriers of varying types and dimensions is possible. Also, accommodating up to three trolleys at the same time is feasible

Precision

- Maximum flexibility: Double-sided loading and unloading without decoupling, enabling the delivery of two different types of production lines within one journey

- Always on track: LiftRunner with B-Frames has excellent directional stability, even at high speed, and in breaking and cornering manoeuvres

Ergonomics

- User-friendly: trolleys can slide easily into the frames

- Easy handling: Thanks to the specially developed uncoupling system and with very little rolling resistance, trolleys can be detached with minimum effort and without back strain

- Optimal load handling: A flexible combination - depending on requirements - of B-, C- or E-Frames and various types of trolleys

Compactness

- Reduction in stock levels and production logistics space: High delivery frequency in synchronised production and logistics processes

- Maximum flexibility: A combination of different frame types within one train for the demand-orientated provision of small batches

- Space-saving: A very tight turning circle enables it to be used in confined areas

Safety

- Reduced accident risk: Increased safety through bundling shipments and reducing truck traffic

- Minimised risk of damage: Automatic safety mechanism when sliding trolleys in

- Safe ramp travel: A combination of rigid and flexible links minimises pitching during acceleration and braking

Environmental Responsibility

- Energy saving: Traffic reduction by bundling together shipments of the same volume therefore avoiding empty journeys

- High process transparency: Supplying and disposing of materials at the same time increases the efficiency of tugger train usage

- Noise and wear and tear: Trolleys are raised up during the journey, so there is no ground contact